Fisher P-75 Eagle - The Fisher P-75 Eagle was an American fighter aircraft designed by the Fisher Body Division of General Motors. Development began in September 1942 in response to a requirement from the United States Air Force for a fighter that has an extremely high rate of climb, with the most powerful liquid-cooled engine available, the Allison V-3420. The program was canceled after only a small number of prototypes and production aircraft were completed, as it was no longer needed in its original role, could not be deployed quickly and had no significant advantages over aircraft already in production.

In October 1942, the contract for two prototypes, designated "XP-75", was signed with GM's Fisher Body Division. The design concept was to use the outer wing panels of the North American P-51 Mustang, the tail assembly of the Douglas A-24 (SBD) and the landing gear of the Vought F4U Corsair in an overall design similar to that of the Bell P .-39 Airacobra with the engine located amidships with the counter-rotating propellers driven via extension shafts. However, at an early stage of design, the outer wing panels of the Curtiss P-40 Warhawk were replaced by the panels of the P-51.

Fisher P-75 Eagle

By mid-1943, the need for long-range escort fighters became more urgent than fast-climb interceptors, so the decision was made to order six more XP-75 aircraft, adapted for the long-range role. At this time, an order was also placed for 2,500 production aircraft, but with the stipulation that if the first P-75A was unsatisfactory, the entire order could be cancelled.

Us Air Force Museum

At the time, Geral Motors was busy with various projects for the war effort, including the mass production of several different types of aircraft, including the Grumman TBF Avger. some sources

Claim that the P-75 was the result of a scheme to prevent Geral Motors from being forced to build Boeing B-29 Superfortresses; the P-75 project is a "high priority" project to help GM avoid the added stress of Superfortress production. The "Eagle" received extensive media coverage prior to its first flight, and was heralded as a "magnificent aircraft."

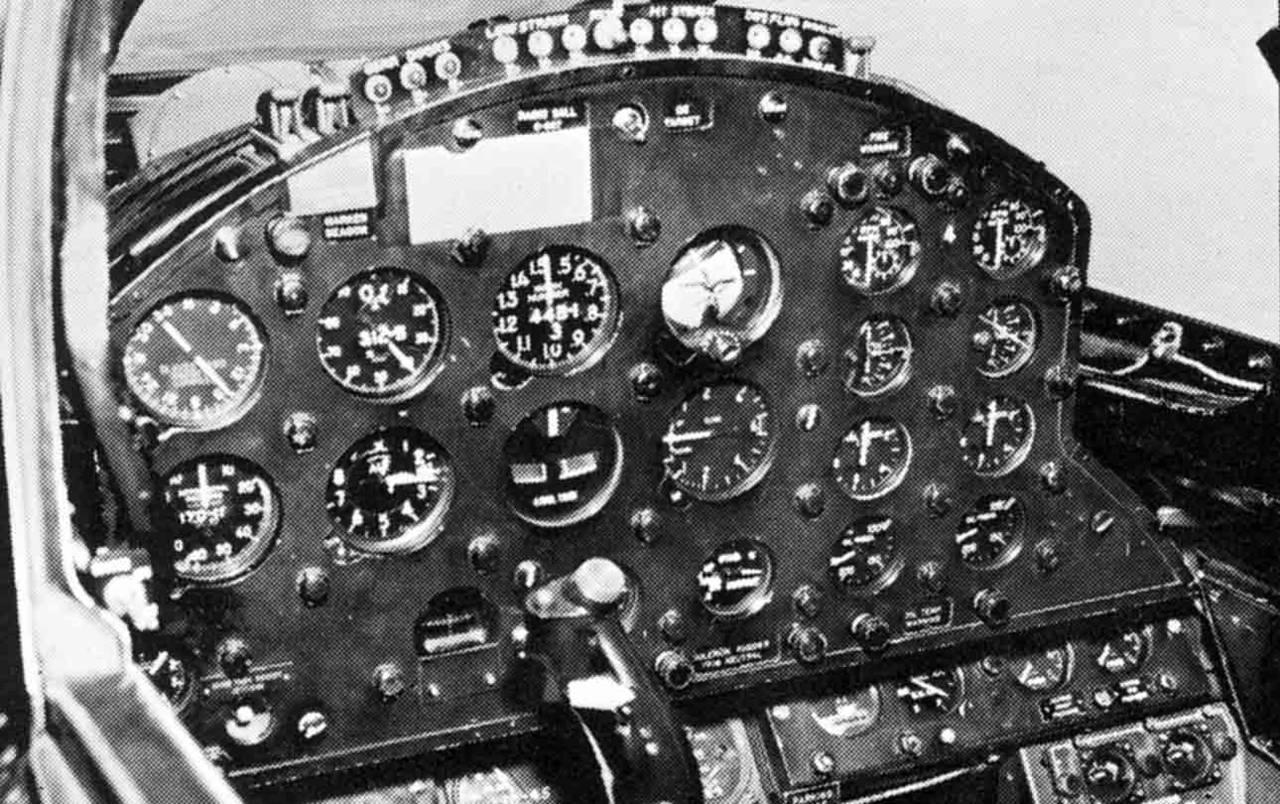

Powered by a 24-cylinder V-3420-19 engine rated at 2,600 hp (1,900 kW) driving counter-rotating coaxial propellers, the XP-75 first flew on 17 November 1943. The second XP-75 flew somewhat later, with the six long-range XP-75s entered the test program in the spring of 1944. The test program posed many early problems, including miscalculation of the fighter's mass character, failure of the engine to produce its expected power, inadequate engine cooling, high aileron forces at high speed, and poor turning characteristics. Redesigns were introduced to the long-range XP-75s, including a modified tail assembly, a new "bubble" canopy, and a V-3420-23 engine that corrected most of the deficiencies when the first P-75A Eagles performed tests. in September 1944.

At the time, the Army Air Forces had decided to limit the number of types of combat aircraft in production and not to go into full production of new types that might not be available before the war ended. As the twin-engine Lockheed P-38 Lightning and the North American P-51 Mustang demonstrated excellent long-range capabilities, production of the P-75A Eagle subsequently ended on October 6, 1944. It was decided to use all six completed production vehicles . aircraft for experimental work and development of the V-3420 engine. As a result of those events, the P-75A did not complete formal performance tests due to the termination of the production contract. In the end, only eight XP-75s and six P-75As were built.

Me 410 \

Fisher P-75 Eagle on display at the National Museum of the USAF in the fourth building that opened in 2016 Donovan (Don) Reese Berlin had worked as a chief engineer for Curtiss-Wright Corporation. He had designed the company's successful P-36 Hawk and P-40 Warhawk fighters. Berlin also designed a series of fighters without success. He left Curtiss-Wright in December 1941 in frustration that he felt the company was not sufficiently supportive of his efforts to develop a new fighter. At the request of the US government, Berlin was quickly hired by General Motors (GM) in January 1942 as director of aircraft development at the Fisher Body Division (Fisher).

The Fisher P-75 Eagle would be developed quickly and cheaply using many existing components. However, a lot of resources were spent on the plane. The first XP-75 (43-46950) had a unique pointed rear. It was also the only example to use a relatively unchanged Douglas A-24 empennage. Note the fixed tailwheel and fairings that covered the machine gun barrels in the nose of the plane.

Fisher had already been contracted by the government to build major assemblies for the North American B-25 Mitchell bomber, and plans for the manufacture of other aircraft components were in the works. It made sense to have a prominent aeronautical engineer on Fisher's staff. In March 1942, Fisher was commissioned to build various components (engine cases, outer wing panels, ailerons, flaps, horizontal stabilizers, elevators, vertical stabilizers, rudders) of the Boeing B-29 Superfortress and 200 complete aircraft. . A new plant would be built in Cleveland, Ohio to support this order. Beyond Fisher, several other GM divisions were involved in building aircraft and aircraft engines under license from other manufacturers. However, GM wanted to design and manufacture its own products to support the war effort. Berlin believed in applying automotive methods to produce airplanes, which was a good match for auto giant GM.

On September 10, 1942, GM, through Fisher, submitted a proposal to the Army Air Force (AAF) for a new interceptor fighter. The proposal was based on an AAF request of February 1942 for such an aircraft with exceptional performance. Fisher's plane was designed by Berlin, powered by an Allison V-3420 24-cylinder engine, and built mainly from parts of other planes. The aircraft provided impressive performance with a top speed of 440 mph (708 km/h) at 20,000 ft (6,096 m), an initial rate of climb of 5,600 fpm (28.5 m/s), a ceiling of service of 38,000 feet (11,582). m) and a range of 2,240 miles (3,605 km) on internal fuel only. All this came with a promise to deliver the first aircraft within six months of the contract being awarded.

Fisher P 75a

The above image shows at least five XP-75A aircraft under construction. The center image, from right to left, shows the first two XP-75 aircraft (43-46950 and 43-46951) and the first two XP-75A aircraft (44-32161 and 44-32162). The second XP-75 (second from the right) has wide H-blade propellers installed, while the other aircraft has narrow A-blade propellers. The bottom image is a P-75A under construction. Note the V-3420 engine. (Veselenak Photo Collection / National Museum of US Air Force Imagery)

In February 1941, the Army Air Corps (name changed to AAF in June 1941) had considered the Allison V-3420 as a possible replacement for the Wright R-3350 engine intended for the B-29. Allison Engineering Company was a division of GM, and at that time, development of the V-3420 focused on making the basic engine and not much else. However, the priority of the V-3420 program was lowered after the Japanese attacked Pearl Harbor on December 7, 1941.

GM had been looking for an application for its Allison V-3420 engine, and the AAF had been trying to entice other manufacturers to include the engine in a fighter design. Fisher's hunting project provided a solution for both entities. The AAF was sufficiently impressed by Fisher's proposal that it approved the construction of two prototypes (series 43-46950 and 43-46951) on October 10, 1942. The aircraft received the designation P-75 Eagle, with the prototypes label XP. 75. . Some believe that the tracking number "75" was issued specifically at the request of Berlin, as their "Model 75" at Curtiss-Wright became the successful P-36 and led to the P-40. Although there were some reservations with the design of the aircraft, it was believed that a team working under the experienced Berlin leadership would solve any problems along the way.

Aircraft 44-32162 was the fourth of the XP-75 series and the second XP-75A with additional fuel tanks in the wings. Note the revised canopy and tail compared to the first prototype. The aircraft has narrow A-blade propellers and 10-gun armament appears to have been fitted.

Fisher P 75a Eagle Valom 72010

The XP-75 was of all metal construction with cloth covered control surfaces. The cockpit was placed near the front of the aircraft and gave the pilot a good forward and downward view. The pilot was protected by 177 lb (80 kg) of armor. The cockpit cover consisted of front and side panels from a P-40. The aircraft's empennage, with a fixed tailwheel, was from a Douglas A-24 Banshee (AAF version of the Navy SBD Dauntless). Initially, the outer wing panels of the North American P-51 Mustang would be attached to the center part of the inverted gull wing that was an integral part of the fuselage. However, the P-51 wings were soon replaced by P-40 wings attached to a normal center section. The main landing gear was from a Vought F4U Corsair and had a nearly 20 foot (6.10 m) wide track. Four .50 caliber machine guns were mounted and delivered in the nose of the aircraft

P 75, p fisher, vizio p 75, p 245 75 r16, fisher xp 75 eagle, p 215 75 r15, p 205 75 15, p 75 eagle, diclofenac p 75 pill, fisher p 75, p 235 75 r15, vizio 75 p series

0 Comments